earth domed children’s nursery

2020 Chesham

construction design | contractor

When I began my 3 year stint at HGMatthews brick manufacturers my brief was simple; refine and test their earth blocks at the BRE to prove their structural capabilities, develop and set up manufacture of other natural building products and build a flagship building to demonstrate them.

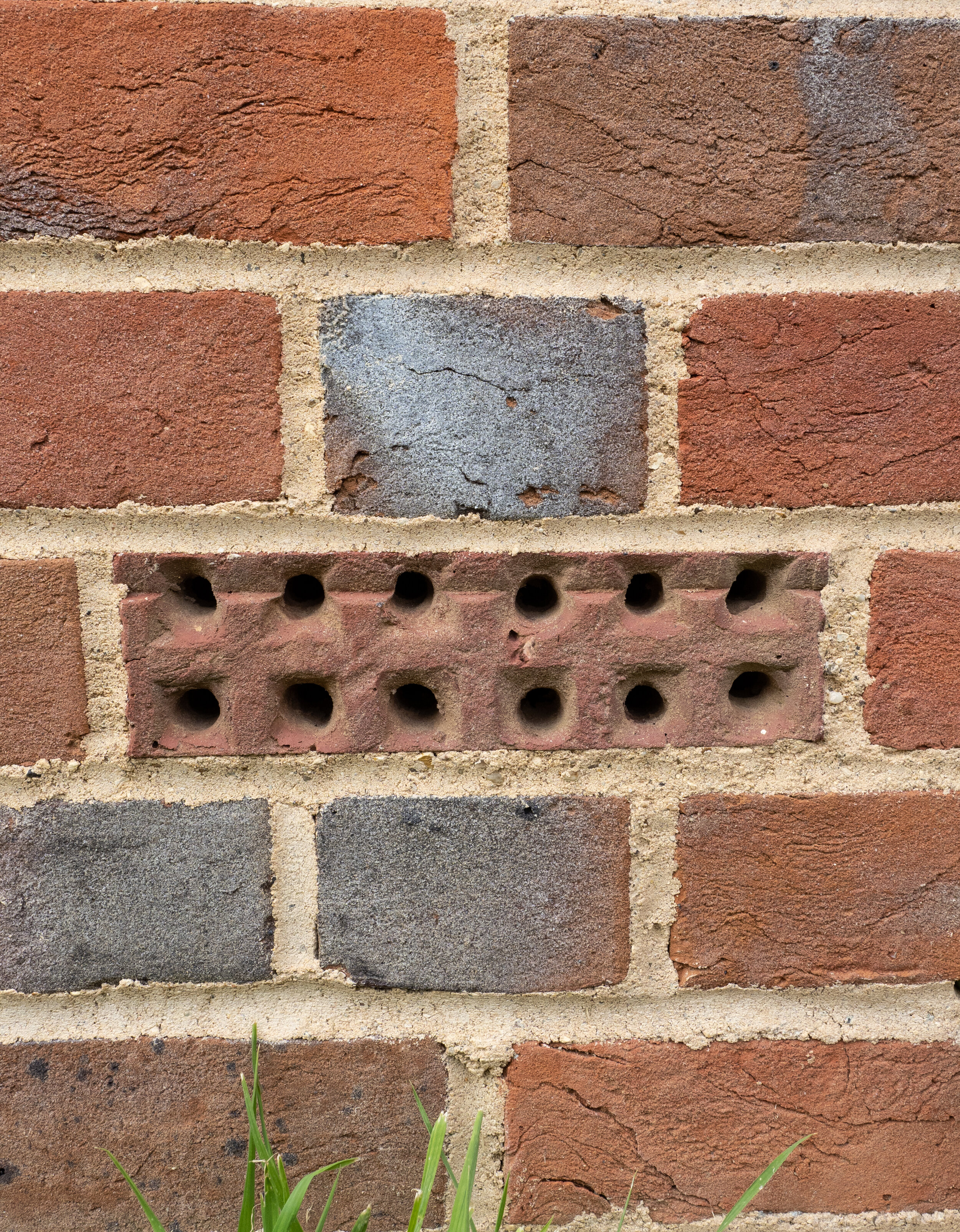

The flagship build was Bellingdon Children’s Nursery and we used as many HGMatthews products as possible. Flint rubble trench foundations, structural earth blocks, insulating hempcrete blocks, facing woodfired bricks, cast hempcrete, loose fill hempcrete, clay plasters and glazed bricks.

The building is amazing and beautiful and provides a very calming atmosphere for the children to learn and play in.

The scheme was designed by renowned earth architect Gernot Minke, I carried out the construction design and built the building with a team of local builders.

The site pegged out.

Andy setting out

Excavation ready for the flint which was sieved out of the neighbouring field.

The excavation was first lined with geotextile.

The flint was laid in 150mm layers and compacted to 100mm. A 100mm thick limecrete top was cast over the flint.

Earth blocks laid out.

Laying the earth blocks in earth mortar.

Below DPC was insulated with foamed glass. Note the foamed glass block at the door opening so the foamed glass aggregate doesn't spill out. The hempcrete blocks were laid directly on the glass foam aggregate.

Glu-lam wall plate on structural earth blocks, with hempcrete block insulation.

These cuts were done by hand but they all came out great.

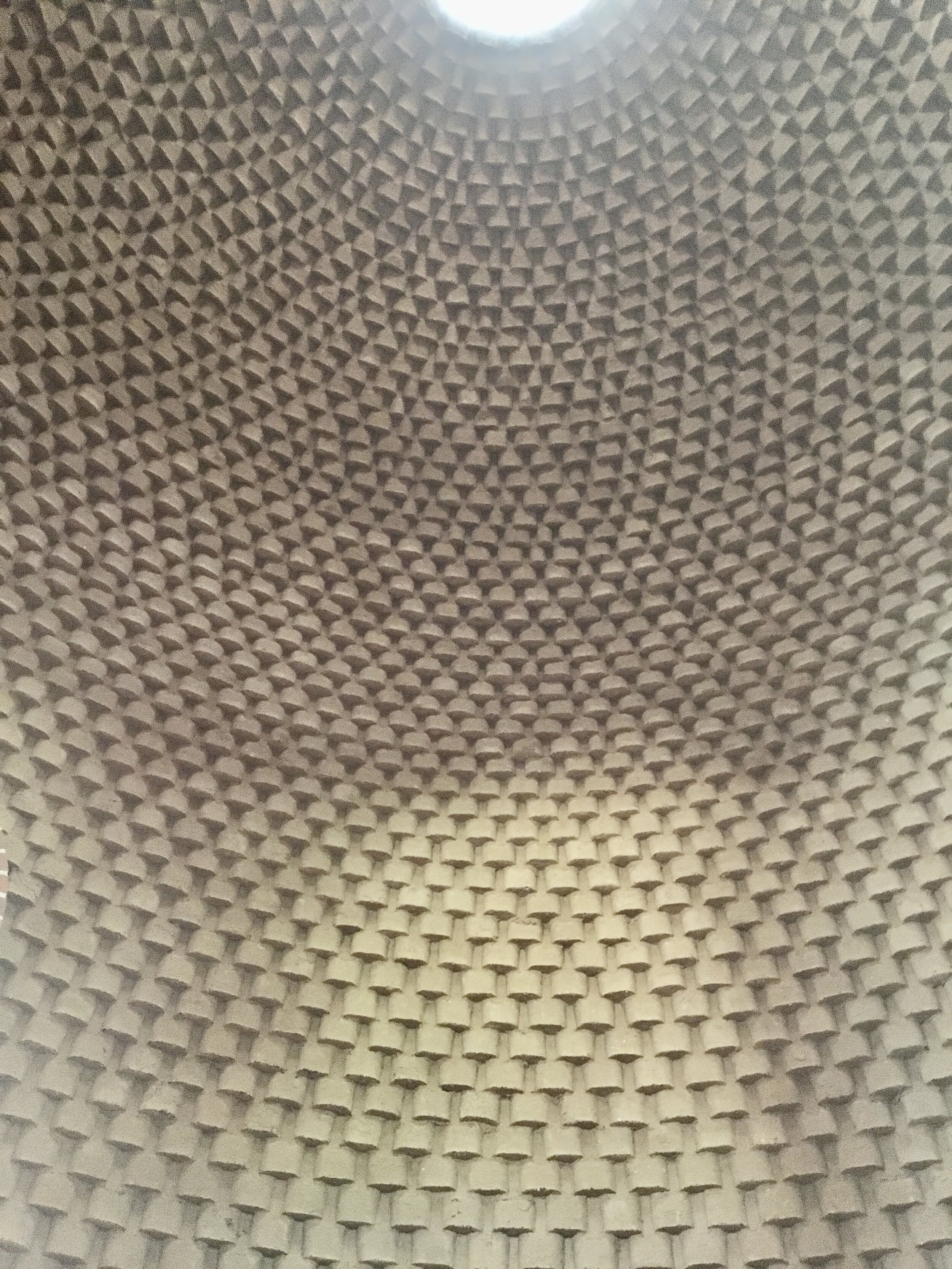

Starting on the earth block dome.

We devised a simple contraption to set out the dome.

A lot of weight on just 160mm thick earth blocks.

The pallets of blocks in the foreground are the hand made dome blocks designed by Gernot Minke.

Finished dome.

We cast hempcrete between the bricks and the glu-lam so we could cast the lintels in.

First we shuttered the underside.

Second we put 50mm of hempcrete in and lay the lintel on.

Then cast the rest of the hempcrete all in one go.

It worked a treat and was so neat we didn't plaster it.

The HGMatthews woodfired bricks are breathable, you can see the water from the cast hempcrete behind drying out more through the bricks than the lime mortar.

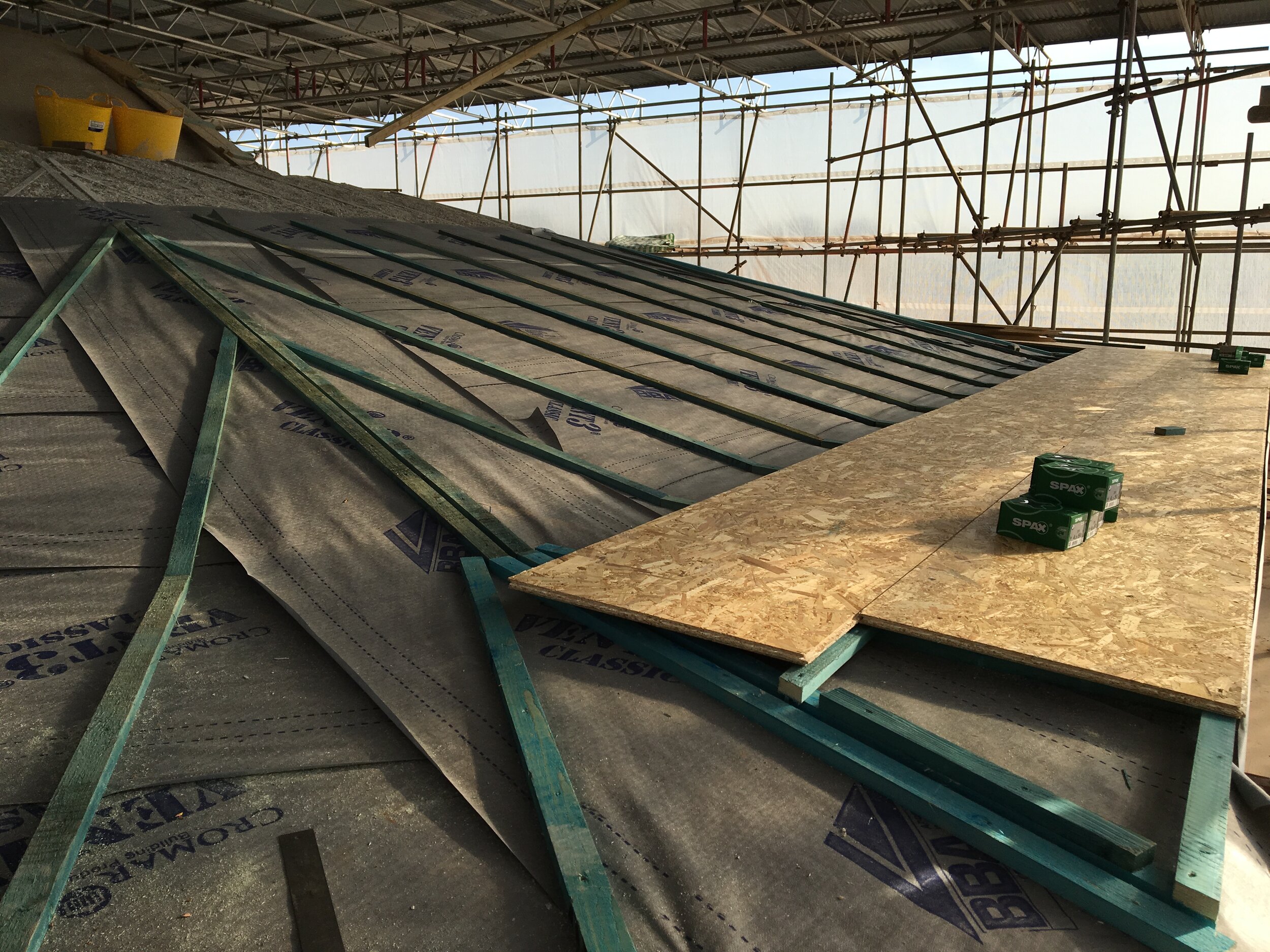

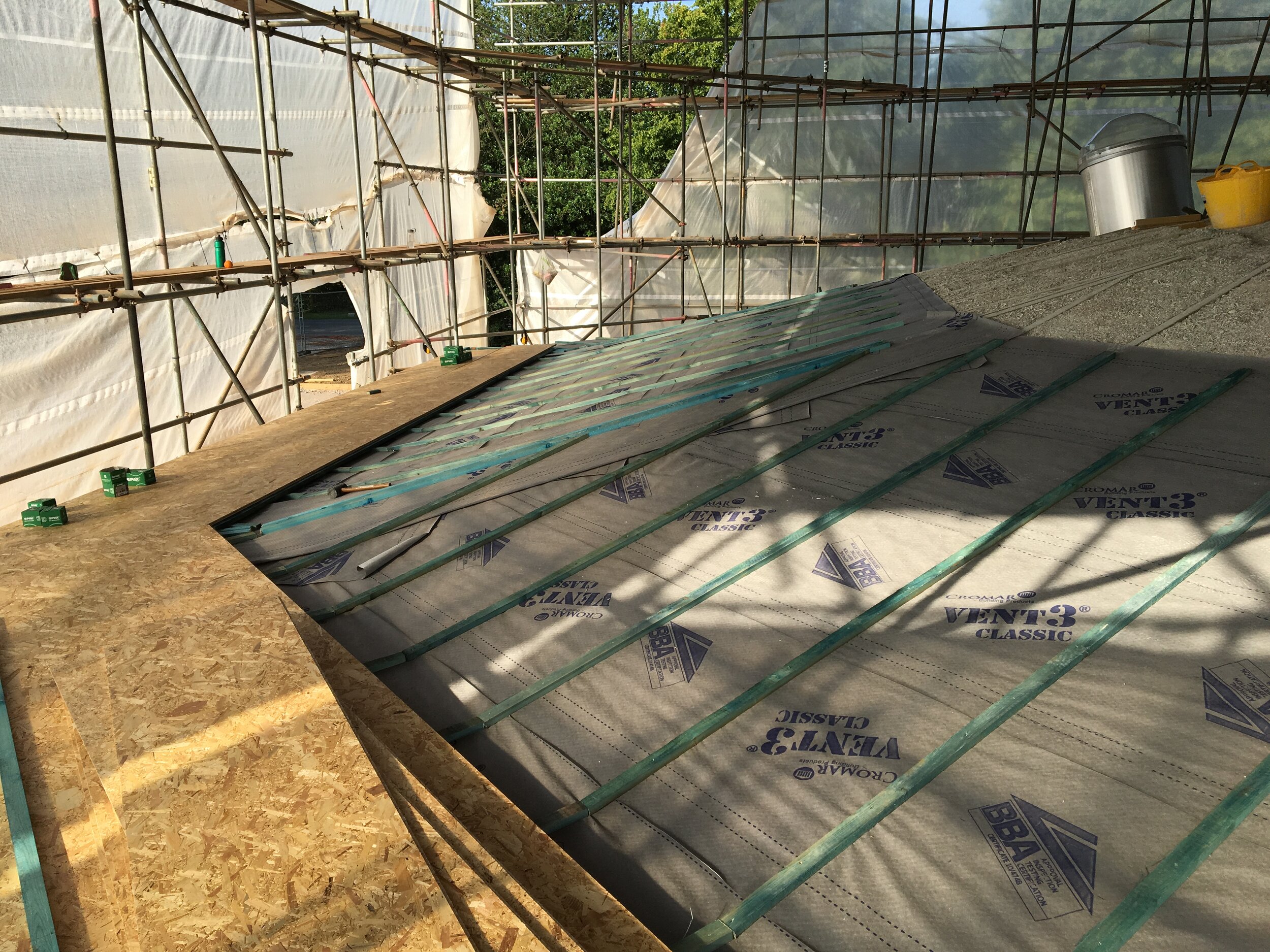

We made some light weight roof mix hempcrete blocks for the roof. This way you don't have to support the weight of the water in wet cast hempcrete and it has the benefit of being pre-dried.

Over the blocks we laid loose fill hempcrete to fill any voids.

Neat job.

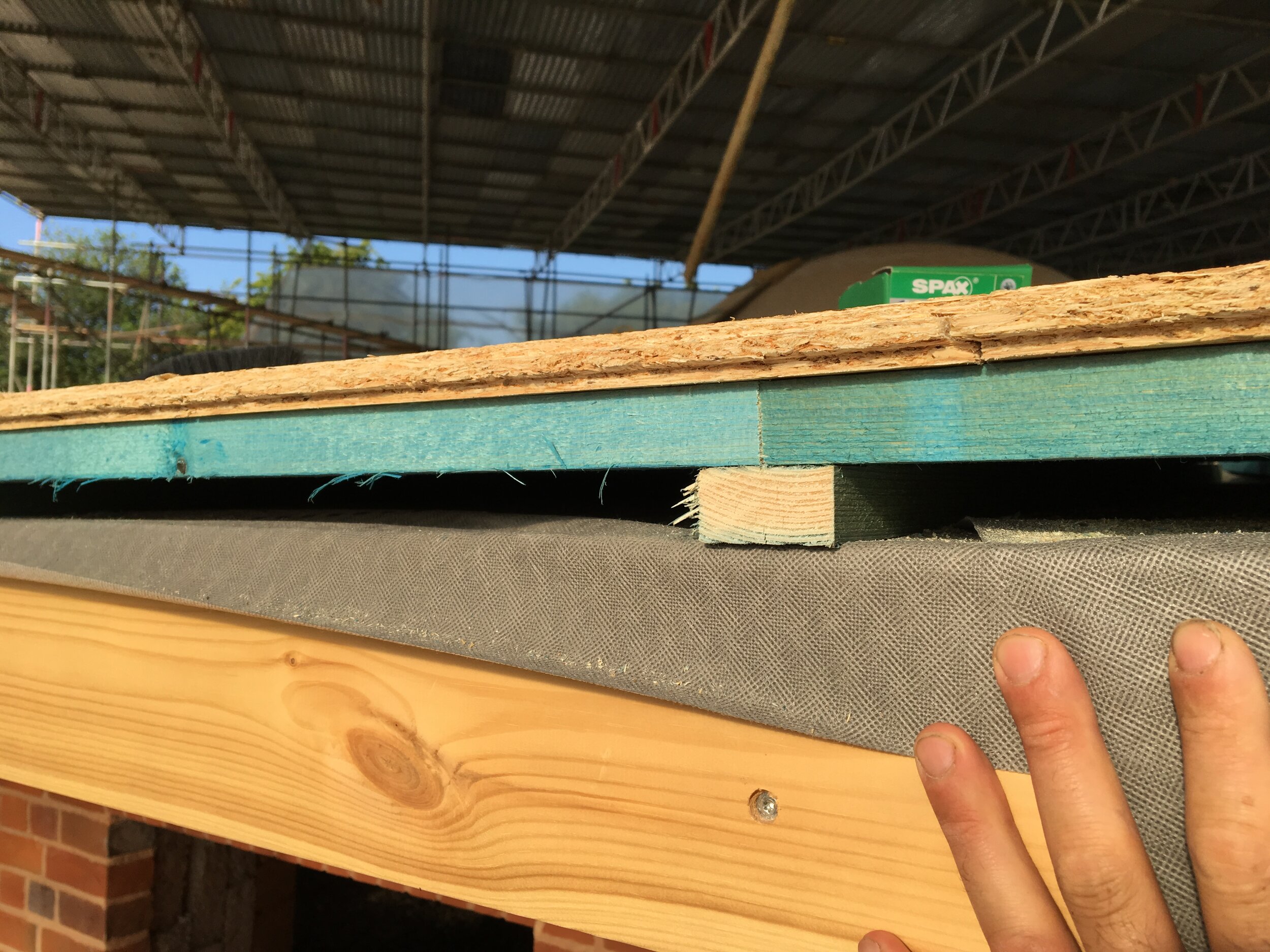

The battens and counter battens over the roof membrane are creating a ventilated space.

Air can move through the 25mm gap into the 50mm vented space and can exit at the roof light at the top of the roof.

The water proof covering is fibre glass under a green roof.

When I have a big limecrete screed to do I call in the limecrete company.

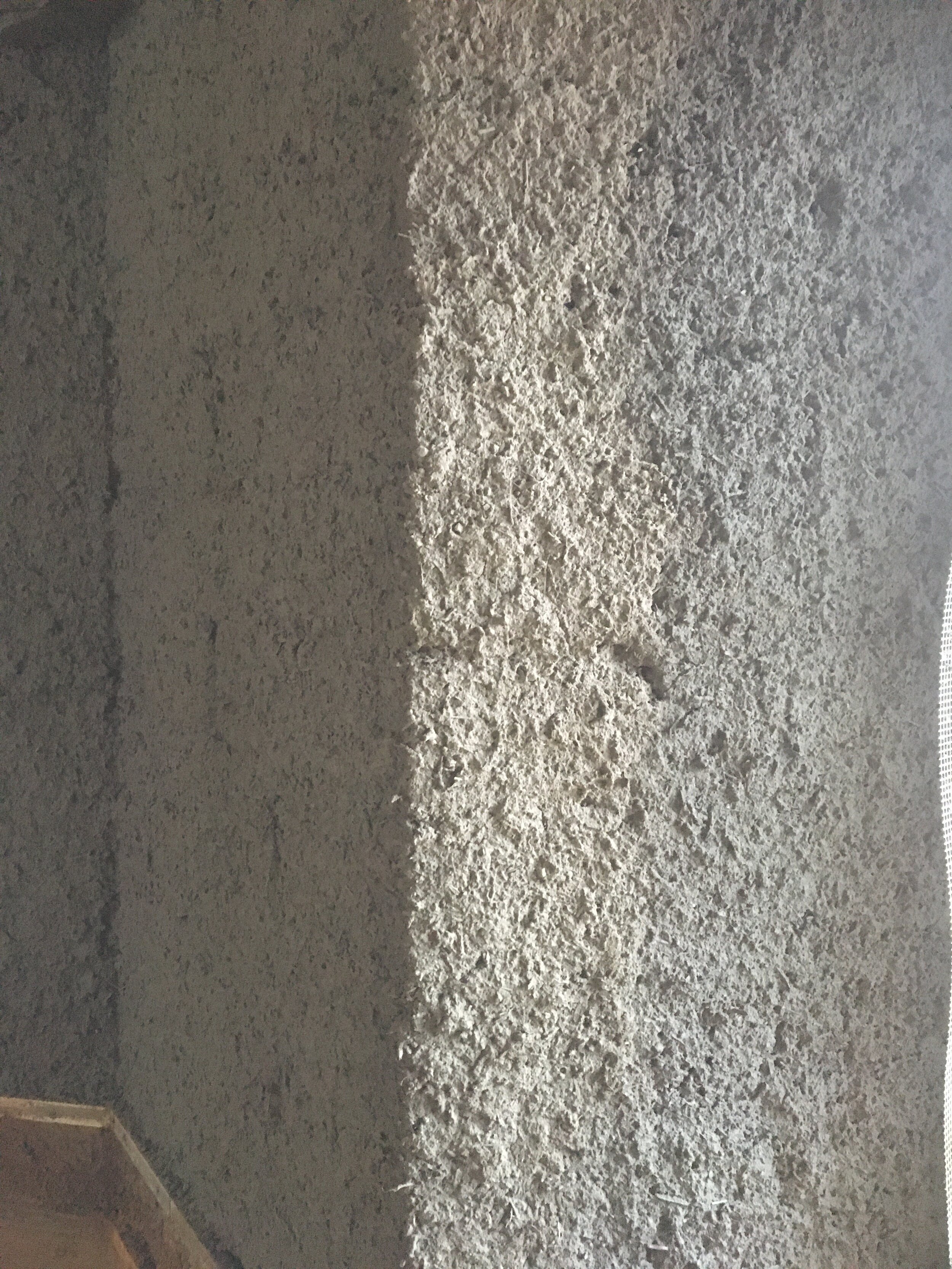

Base coat clay plaster after being sprayed on, before ruling off.

Base coat clay plaster after being sprayed on, before ruling off.

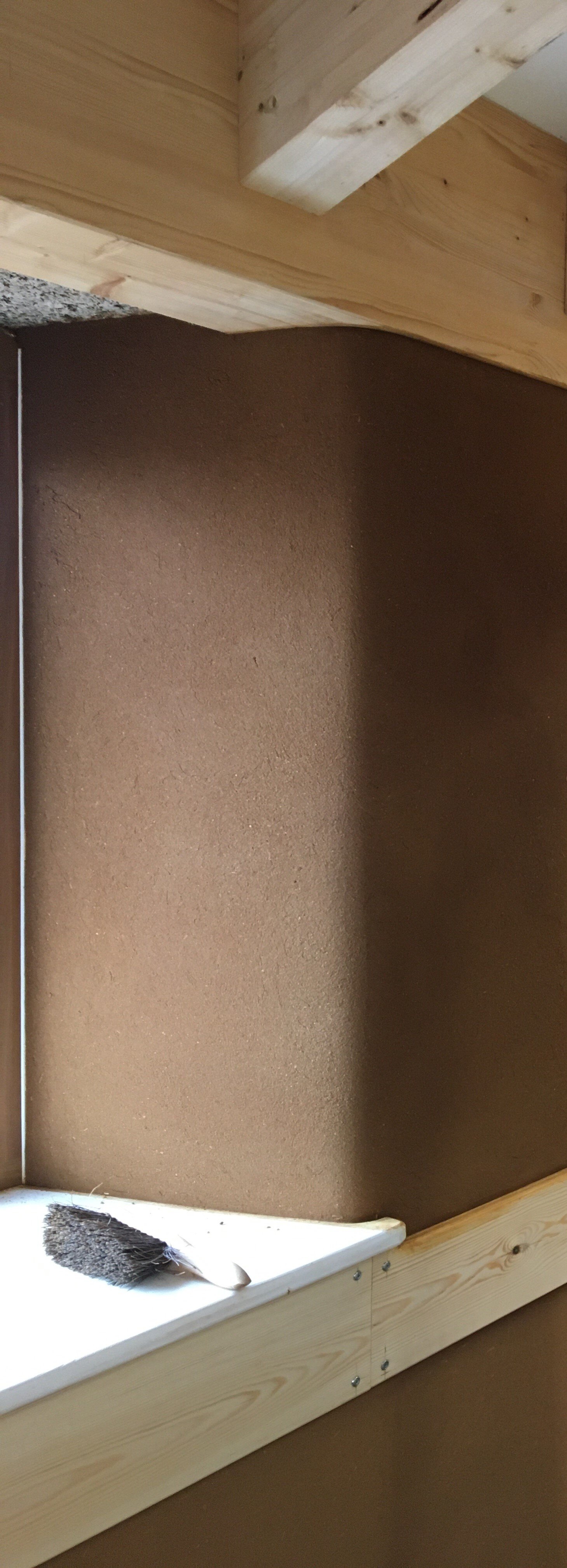

The outside of the dome got two coats of clay plaster.

Soft window reveals, the float finish plaster also reflect a soft light.